Inloggad som:

Kirjaudu sisään

Uusi tili

Haluatko verkkoasiakkaaksi? Napsauta alla olevaa painiketta pyytääksesi tilin avaamista.

Unohtunut salasana

Anna sähköpostiosoitteesi ja valitse ”Lähetä”. Saat ohjeet sisäänkirjautumiseen sähköpostitse.

Mitä on AdBlue® ja miksi sitä tarvitaan?

AdBlue® on tuote, jota käytetään ajoneuvoissa, joissa on pakokaasujen puhdistusjärjestelmä SCR-tekniikalla. Nykyään tekniikka on käytössä lähes kaikissa henkilöautoissa ja raskaissa ajoneuvoissa, joissa on dieselmoottori. Nimestään huolimatta AdBlue® on väritön neste, joka koostuu deionisoidun veden ja 32,5-prosenttisen urean seoksesta. Neste on myrkytöntä ja vaaratonta käsitellä.

SCR-tekniikka

SCR tarkoittaa "selektiivistä katalyyttistä pelkistämistä", ja se on tekniikka, joka puhdistaa dieselmoottoreiden pakokaasut. Jotta tekniikka toimisi, AdBlue®-nestettä on ruiskutettava pakojärjestelmään.

Pienentää päästöjä

SCR:n käyttö vähentää haitallisten typen oksidien päästöjä jopa 90 prosenttia.

Kehitys menee eteenpäin

Vertailun vuoksi voidaan todeta, että 70-luvun puolivälin auto tuottaa yhtä paljon typen oksideja (NOx) ja hiukkaspäästöjä kuin sata uutta autoa. Euro 1 -luokan dieselautoon (1992) verrattuna Euro 6 -luokan dieselauto tuottaa 95 prosenttia vähemmän typen oksideja ja 97 prosenttia vähemmän hiukkasia.

AdBlue® Arom-dekorilta

Voit aina olla luottavaisin mielin, että valitset Arom-dekorin AdBlue®-toimittajaksi. Teemme jatkuvasti testejä varmistaaksemme, että AdBlue® on oikeanlaatuista. Otamme näytteitä kaikista valmistamistamme eristä, ja kaikki tuottamamme AdBlue® on täysin jäljitettävissä, jotta voimme varmistaa, että toimitamme aina parasta laatua.

OMA ADBLUE®-TANKKAUSASEMA

Arom-dekor myy ja vuokraa AdBlue®-tankkausasemia. Oma tankkausasema helpottaa huomattavasti, kun AdBlue®:n tarve on suuri, kuten esimerkiksi kuljetusyrityksessä.

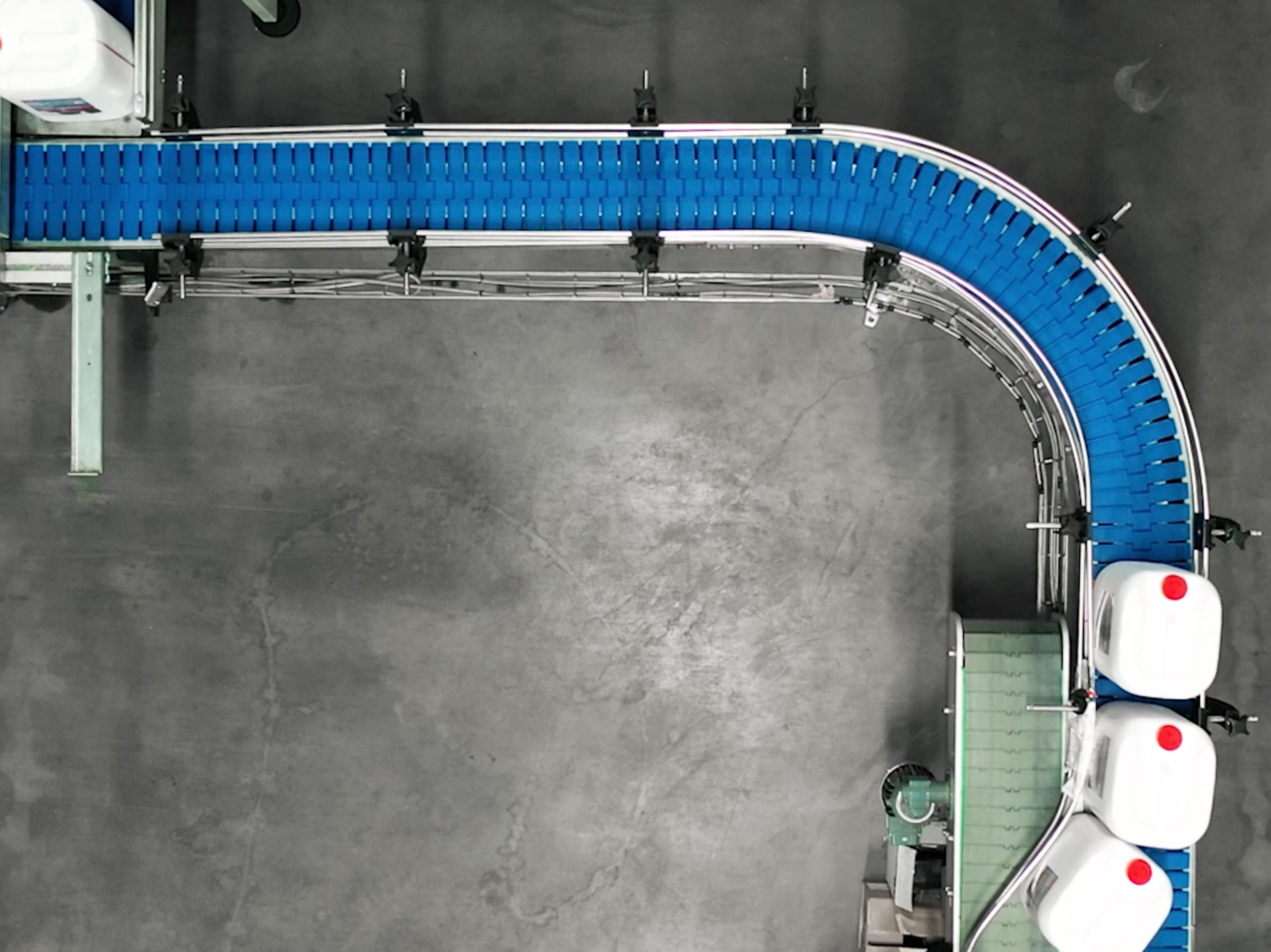

BULKKITOIMITUS - PÄIVITTÄINEN JAKELU KUORMA-AUTOLLA

Kun kyseessä on bulkkitoimitus, säiliöautot tulevat täyttämään säiliösi. Voit saada säännöllisiä bulkkitoimituksia tai tilata tarpeen mukaan. Hoidamme päivittäin bulkkitoimituksia. Toimitamme useimmille paikkakunnille Suomessa ja tarjoamme lyhyet toimitusajat.

ADBLUE® PAKKAUKSESSA

Arom-dekor Kemi tarjoaa AdBlueta® useissa eri pakkauskokoluokissa - kaikkiin tarpeisiisi.

- IBC - 1000 Litraa

Suurimmat pakkauksemme bulkkitoimitusten lisäksi. Kun ostat 1000 litran vaihtoehdon, se toimitetaan IBC-säiliössä. - Tynnyri - 210 litraa

Toiseksi suurin vaihtoehto. Saatavilla on tietenkin pumppuja, joilla nestettä voidaan helposti käsitellä tynnyreissä. - Kanisteri - 5, 10 ja 20 litraa

Kanisteri on helpommin hallittavissa oleva vaihtoehto. Tarjoamme AdBlueta® 5, 10 ja 20 litran kanistereissa.

AdBlue on tuote, josta keskustellaan usein eikä tämä ole sattumaa. Todennäköisesti syy siihen, miksi siitä jatkuvasti keskustellaan, on se, että monet ovat vahvasti riippuvaisia AdBluesta. Kyseessä on asia, joka koskee kaikkea hintojen määrittelystä urean alkuperään, sen toimintaan ja niin edelleen. Siksi aikomuksemme on selventää yleisimpiä kysymyksiä AdBluesta tässä.

Ostaako Arom-dekor Kemi ureaa Venäjältä?

Ei, me emme osta. Kun Venäjä aloitti hyökkäyssotansa Ukrainaa vastaan, Arom-dekor teki välittömästi päätöksen olla ostamatta mitään raaka-aineita Venäjältä. Päätös perustuu vahvoihin arvoihimme ja vakaumukseemme. Meille on itsestään selvää, että seisomme ihmisoikeuksien ja sortoa kärsivien solidaarisuuden puolella. Olemme päättäneet toimia arvojemme mukaisesti myös tulevaisuudessa ja toivomme, että yhä useammat yritykset ja organisaatiot seuraavat meitä ihmisoikeuksien ja oikeudenmukaisuuden puolustamisessa.

Kuka saa valmistaa AdBlueta?

Tuotetta voidaan kutsua AdBlueksi vain, jos se on valmistettu eurooppalaisen standardin ISO/PAS 22241-1 mukaisesti. Tuotenimi AdBlue® on Saksan Autoteollisuusliiton VDA:n omistama ja valvoma. Arom-dekor Kemi Oy täyttää VDA:n kaikki vaatimukset.

Mistä ja miten AdBlueta voi ostaa?

AdBlueta on saatavilla monista paikoista, kuten autokorjaamoista ja huoltoasemilta. Myymme AdBlue®-tuotteitamme pakkauksissa, jotka vaihtelevat 4 litrasta aina kokonaisiin tankkiautotoimituksiin asti.

Kuinka kauan AdBlue säilyy?

Tuotteen säilyvyysaika on 18 kuukautta tuotantopäivämäärästä, edellyttäen että se säilytetään suositusten mukaisesti. AdBlueta ei saa sekoittaa muihin nesteisiin.

Miten AdBlueta kuljetetaan ja varastoidaan?

AdBlue on suhteellisen vaaratonta eläimille ja ihmisille. Neste ei ole myrkyllinen eikä se voi räjähtää tai syttyä, ja sitä voidaan kuljettaa ja varastoida minimaalisella riskillä. AdBlue kiteytyy lämpötilan ollessa alle -11 °C. Jos neste jäätyy, se voidaan sulattaa ja käyttää uudelleen. AdBlueta ei saa varastoida suorassa auringonvalossa, koska se voi johtaa tuotteen erottumiseen. Jos neste erottuu, se on käyttökelvotonta. AdBluen jäämiä, valkoisia läikkiä, voi helposti poistaa lämpimällä vedellä.

MIKSI VALITA AROM-DEKOR?

Meiltä voit tilata kaikentyyppiset pakkaukset tai toimitukset suoraan verkkokaupastamme. Tarjoamme tarpeisiisi sovitetun kokonaisratkaisun.

BULKKITOIMITUKSIA KOSKEVIA KYSYMYKSIÄ?

Onko sinulla kysyttävää bulkkitoimituksistamme tai tankkausasemista, joissa on valvontajärjestelmä? Älä epäröi ottaa meihin yhteyttä, autamme mielellämme!